Compositional Effects of Bond Coat on CorrosionBehavior of HVAF-sprayed Bi-layer Coatings

Authors: Ph. D. Esmaeil Sadeghimeresht, Prof. Nicolaie Markocsan, Prof. Per Nylén

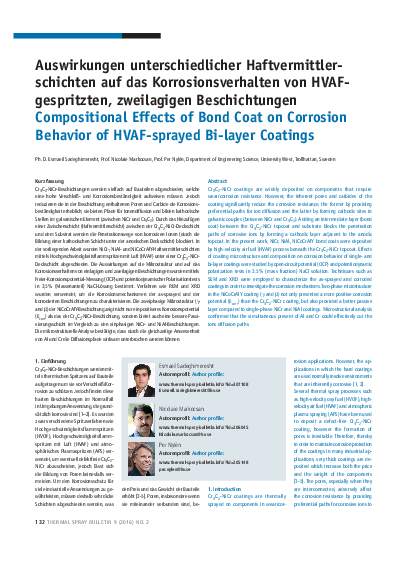

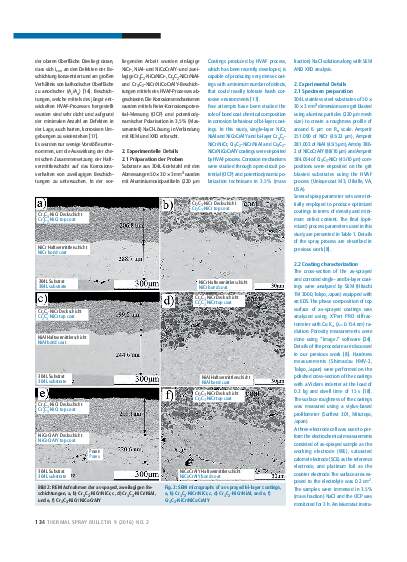

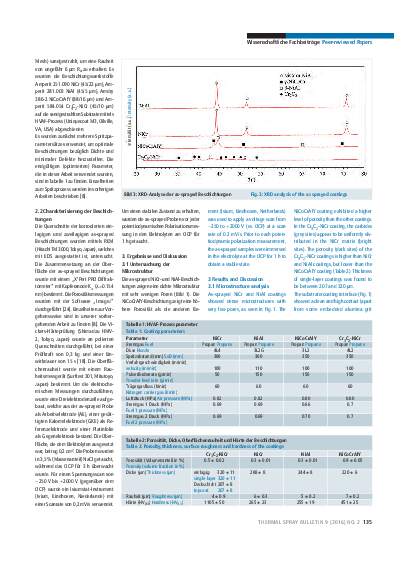

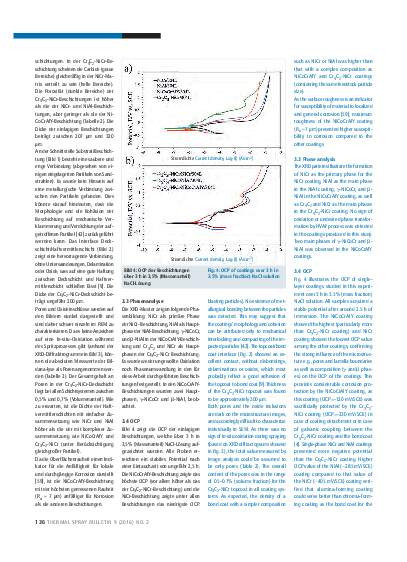

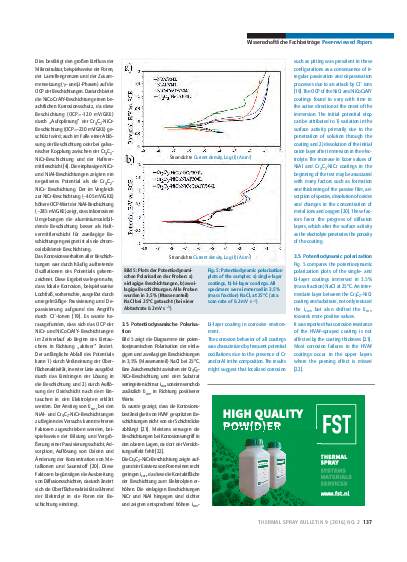

Cr3C2-NiCr coatings are widely deposited on components that require wear/corrosion resistance. However, the inherent pores and carbides of the coating significantly reduce the corrosion resistance, the former by providing preferential paths for ion diffusion and the latter by forming cathodic sites in galvanic couples (between NiCr and Cr3C2). Adding an intermediate layer (bond coat) between the Cr3C2-NiCr topcoat and substrate blocks the penetration paths of corrosive ions by forming a cathodic layer adjacent to the anodic topcoat. In the present work, NiCr, NiAl, NiCoCrAlY bond coats were deposited by high-velocity air fuel (HVAF) process beneath the Cr3C2-NiCr topcoat. Effects of coating microstructure and composition on corrosion behavior of single- and bi-layer coatings were studied by open-circuit potential (OCP) and potentiodynamic polarization tests in 3.5% (mass fraction) NaCl solution. Techniques such as SEM and XRD were employed to characterize the as-sprayed and corroded coatings in order to investigate the corrosion mechanisms. Two-phase microstructure in the NiCoCrAlY coating (? and ?) not only presented a more positive corrosion potential (Ecorr) than the Cr3C2-NiCr coating, but also provided a better passive layer compared to single-phase NiCr and NiAl coatings. Microstructural analysis confirmed that the simultaneous present of Al and Cr could effectively cut the ions diffusion paths.

Pages: 132 - 139

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription