Influence of the spraying distance between the shroudoutlet and the substrate surface on the pseudoelasticbehaviour of NiTi twin wire arc sprayed coatings

Authors: Prof. Dr.-Ing. Dipl.-Wirt.Ing. Wolfgang Tillmann, Dipl.-Ing. Mohamed Abdulgader, Prof. Dr.-Ing. Michael Pohl, Dipl.-Ing. Julia Baak

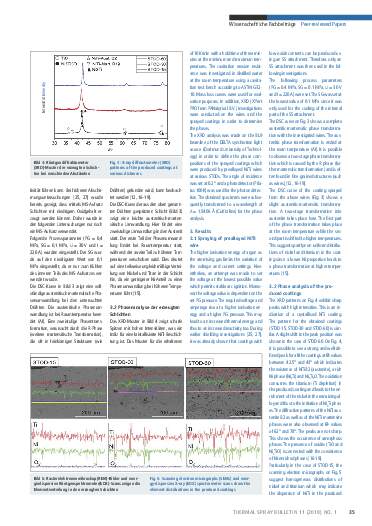

The pseudoelastic behaviour of NiTi shape memory alloys (SMAs) is a promising material property in relation to raising the cavitation erosion resistance. The manufacture of coatings made of NiTi SMAs is technically complicated and, in many cases, is carried out in high vacuum conditions in order to avoid the oxidation of Ti and thus to preserve the pseudoelastic behaviour of NiTi SMAs. Within the framework of the IGF project entitled Cavitation protection coatings made of nickel-titanium shape memory alloys manufactured using modified arc spraying processes, shroud attachments were developed and their effects on the oxide contents and phase transformations of the arc-sprayed coatings were investigated. Attachments which are based on the gas shroud (GS) concept and use the emerging argon as the shrouding gas as well as attachments in the form of solid shrouds (SSs) were developed and investigated. The application of the SS concept led to very low oxide contents as well as to proven phase transformation. The spraying distance between the SS outlet and the substrate surface plays a significant role in this respect. Pseudoelastic behaviour of the coating and thus better cavitation erosion resistances are achieved at a shorter spraying distance. The use of argon as the atomising and shrouding gas in connection with an SS attachment would be an alternative to the spraying of prealloyed NiTi SMA wires. Expensive vacuum technology is not needed in this case.

Pages: 32 - 37

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription