Influencing and disturbing variables in relation to the feed stabilities of powder feed systems with different control concepts

Authors: Dipl.-Ing. Tim Königstein, M. Eng. Christian Schmengler, Dr.-Ing. Andreas Wank, B. Eng. Melissa Mülln

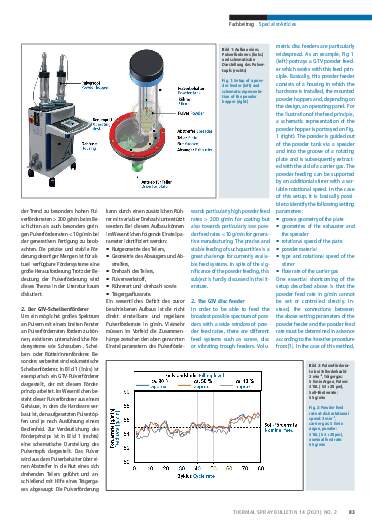

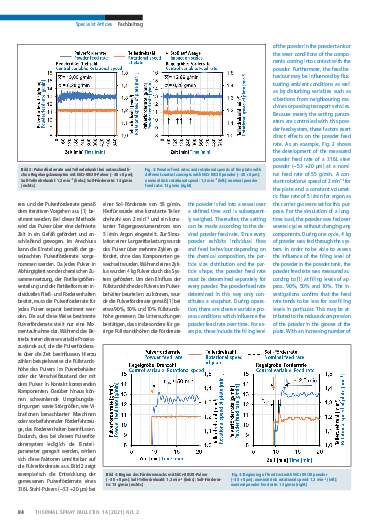

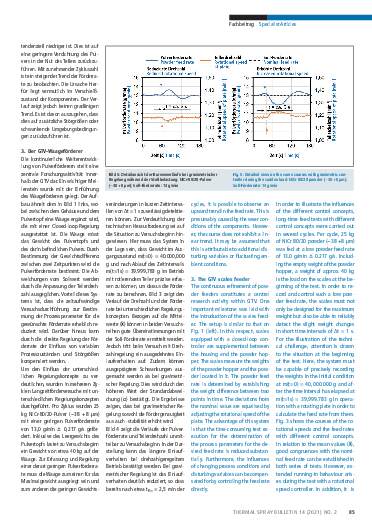

The precise and stable feeding of powders is a basic prerequisite for thermal spraying and laser beam surface welding in order to be able to manufacture high-quality coatings and structures. The volumetric disc feeder frequently used in industry works with a rotation-al speed controller. In this publi-cation, it is shown that, when this control concept is utilised, provi-sion must be made for a greater scope of preparation work and only limited feed accuracy and stability are achieved. That may lead to impairments in the com-ponent quality. Modern, gravi-metric powder feed systems are equipped with scales with which the current feed rate can not only be determined but also controlled. Therefore, it is possible to compensate for the influences of disturbing variables and changing process conditions. This becomes noticeable in higher feed accuracy and stability.

Pages: 82 - 86

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription