Development of near net shape coatings for wearand corrosion protection

Authors: Dipl.-Min. Tim Bause, Prof. Dr.-Ing. habil. Dr.-Ing. E.h. Dr. h. c. Friedrich-Wilhelm Bach, Prof. Dr.-Ing. habil. Kai Möhwald, Dipl.-Min. Martin Erne

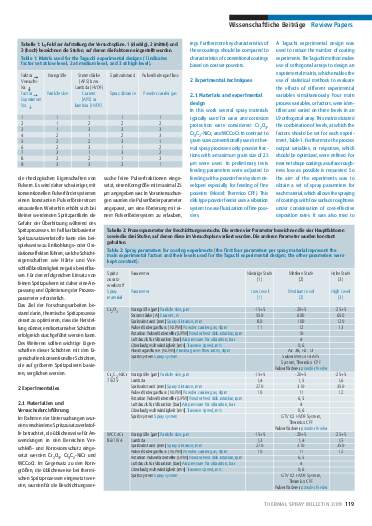

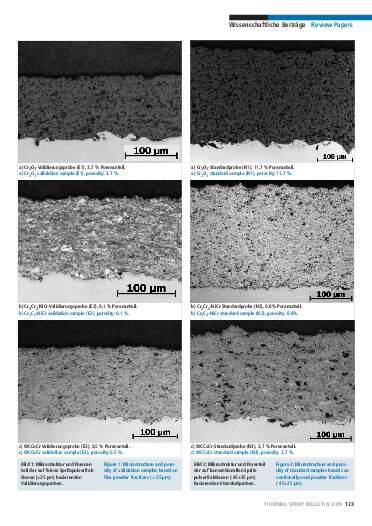

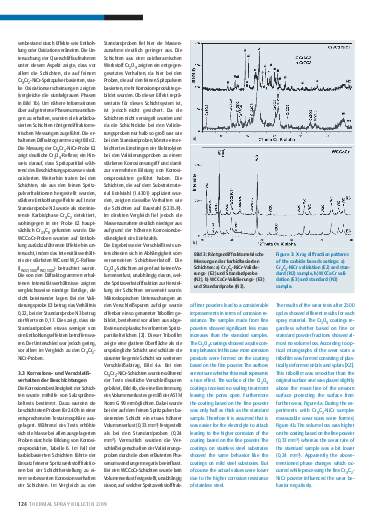

In this work several powder materials typically used for wear and corrosion protection (WCCoCr, Cr3C2-NiCr, Cr2O3) were considered for developing near net shape coatings. In contrast to grain sizes commonly used in thermal spray processes the grain sizes of all examined powders were specified with maximum 25 μm (-15+5 μm, -20+5 μm, -25+5 μm). During the coating experiments the HVOF process was used to apply carbide based powder materials (WCCoCr, Cr3C2-NiCr) whereas the APS process was used to apply Cr2O3 coatings. Taguchi

techniques were utilized in order to reduce the number of experiments and to evaluate and to adjust main process variables. The effectiveness of these techniques could be verified by spraying validation samples successfully. The coatings were examined in terms of deposition efficiency, surface roughness, hardness, porosity, wear and corrosion resistance. The results showed that improvements in terms of porosity, surface roughness and corrosion resistance could be reached by introducing fine spray materials in the spray process.

Reducing the influence of effects like decarburization or oxidation caused by the overheating of small spray particles should be considered in future work.

Pages: 118 - 125

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription