Development of wear protection materials on the basis of amorphously solidifying alloys with particle reinforcement

Peer-reviewed Papers

Authors:

Prof. Dr.Ing. habil. Bernhard Wielage,

Prof. Dr.-Ing. habil. Thomas Lampke,

Dr.-Ing. habil. Hanna Pokhmurska,

Prof. Dr.-Ing. habil. Christian Rupprecht,

Dipl.-Ing. Rico Drehmann

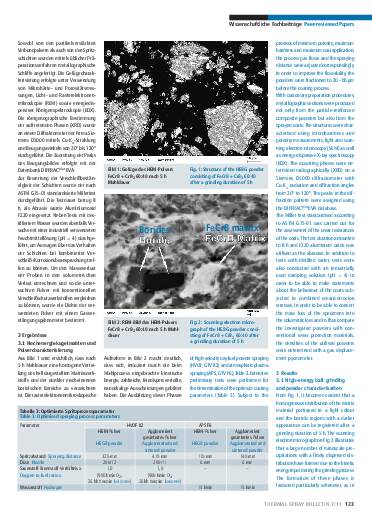

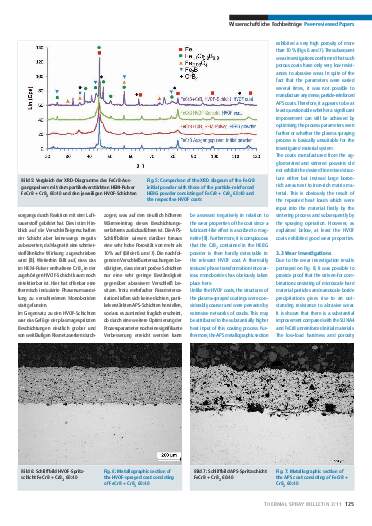

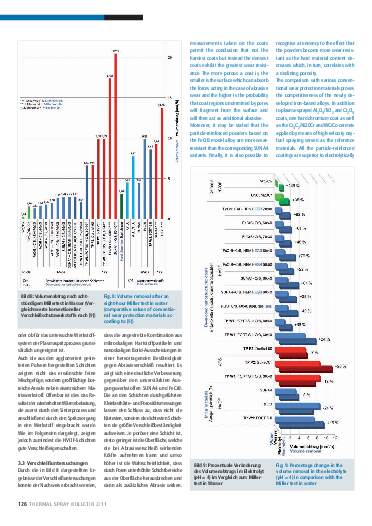

High-energy grinding as well as agglomeration and sintering were used in order to manufacture amorphously solidifying and nanostructured, iron-based powders with varying chromium diboride contents. The further processing of the particle-reinforced materials was carried out by means of high-velocity oxy-fuel powder spraying and atmospheric plasma spraying. In the case of the further processing using HVOF spraying technology, that metastable structural condition of the powder set by the grinding process resulted in coats which exhibited low porosities and high hardnesses and were characterised by a mixed structure consisting of boridic precipitations with a nanodispersed distribution and microscale hard material particles. In the standardised abrasive wear test (Miller test according to ASTM G75-01), it was possible to prove the outstanding wear resistances of the developed iron-based materials not only in water but also in an industrially used damping solution.

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.