Development of cost-effective hardmetal coating solutions for high-temperature applications Part two: Effect of heat treatment and tribological properties

Authors: Dr.-Ing. Lutz-Michael Berger, Dr.-Ing. Richard Trache, Dr. Filofteia-Laura Toma, Dipl.-Min. Sven Thiele, Dipl.-Phys. Jonas Norpoth, M. Sc. Leo Janka

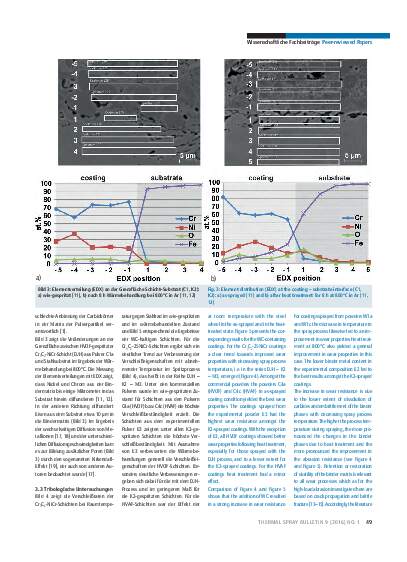

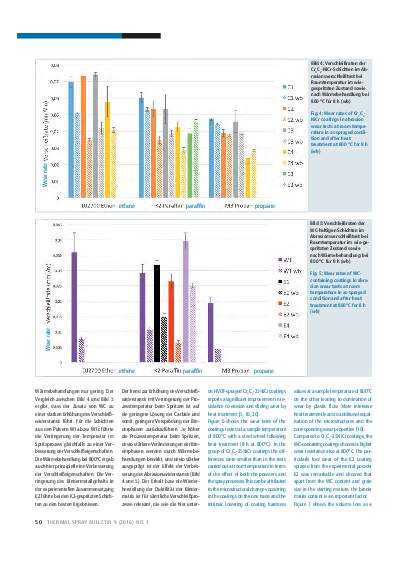

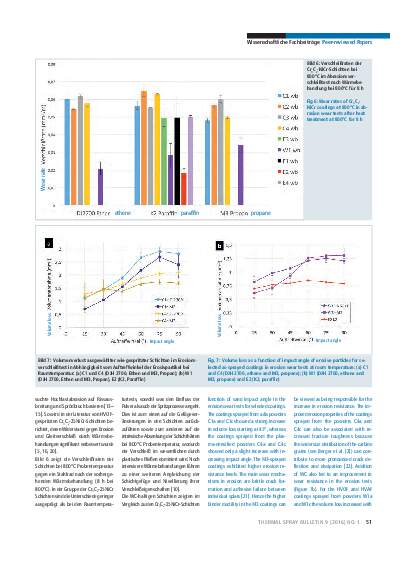

The aim of the present work was to investigate the effect of feedstock powder properties and the spraying process on the performance capabilities and cost-effectiveness of preparation of Cr3C2-NiCr coatings by high velocity oxy-fuel (HVOF) and high velocity air-fuel (HVAF) spray processes. Based on the results specific

improvements were targeted. In part two of this study the effect of heat treatment on coating properties and the resistance of the coatings against abrasion and erosion are discussed. To improve the tribological properties it is necessary to minimise the content of dissolved carbides in the binder matrix to avoid

embrittlement and corresponding cracking susceptibility. This can be achieved either by decreasing the process temperature and increasing the particle velocity during spraying or by heat-treating the sprayed

coatings. The WC-containing compositions were found to exhibit improvements in both performance characteristics and cost-effectiveness of coating preparation and offer considerable potential for

further improvement.

Pages: 45 - 53

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription