Development of cost-effective hardmetal coating solutions for high-temperature applications Part one: Feedstock powders, cost-effectiveness and coating properties

Authors: Dr.-Ing. Lutz-Michael Berger, Dr.-Ing. Richard Trache, Dr. Filofteia-Laura Toma, Dipl.-Min. Sven Thiele, Dipl.-Phys. Jonas Norpoth, M. Sc. Leo Janka

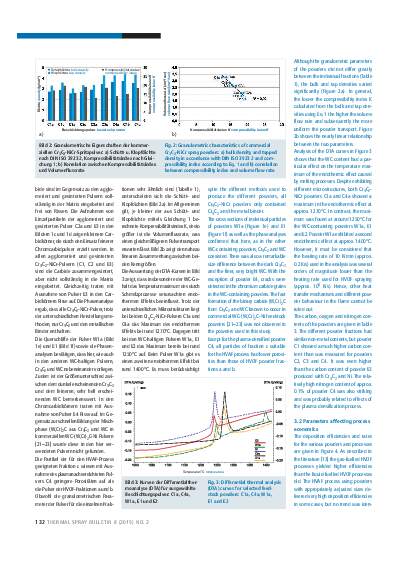

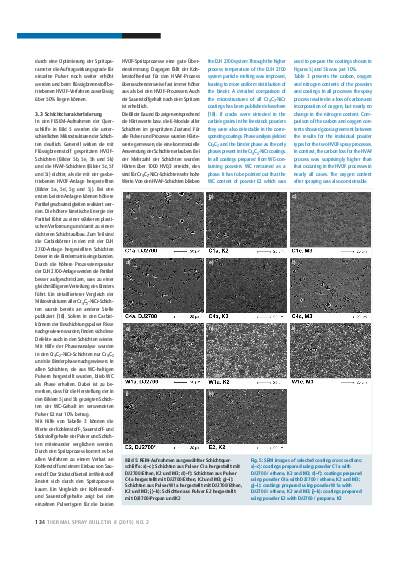

The aim of the present work was to investigate the effect of feedstock powder properties on the cost-effectiveness of the preparation and the performance capabilities of Cr3C2-NiCr coatings prepared

by high velocity oxy-fuel (HVOF) and high velocity air-fuel (HVAF) sprayprocesses. Coatings were prepared from four different commercial Cr3C2-NiCr feedstock powders of spherical morphology produced using different methods and exhibiting different carbide grain sizes and porosities. HVOF with gaseous or liquid fuel or HVAF spray processes were used. The deposition efficiencies and rates were determined. The effects of WC additions, binder metal content and grain size of the initial Cr3C2 powder were investigated on one commercial and four experimental powders. In part one of this study the coating microstructures and mechanical properties are described by means of detailed granulometric and structural feedstock powder analyses as well as the spray processes used.

Pages: 126 - 136

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription