Production of finely structured coating systems with the aid of ultrasonic excitation during arc wire spraying

Authors: Prof. Dr.-Ing. Dipl.-Wirt.Ing. Wolfgang Tillmann, Dipl.-Wirt.-Ing. Leif Gereon Hagen, Dipl.-Chem. Jens Nellesen, B. Sc. David Kokalj

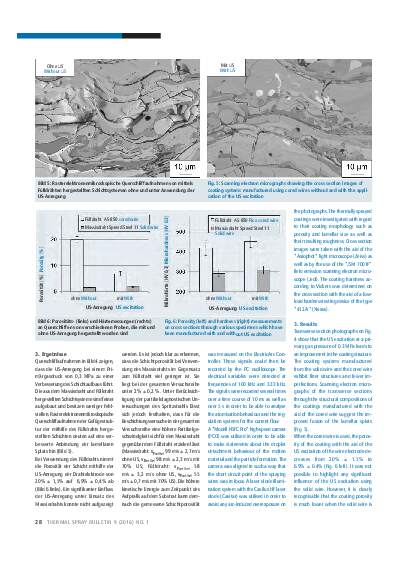

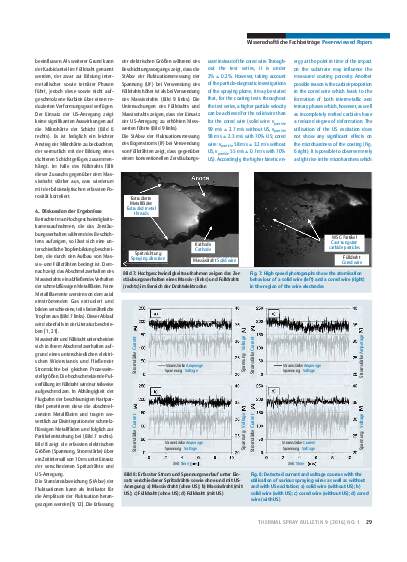

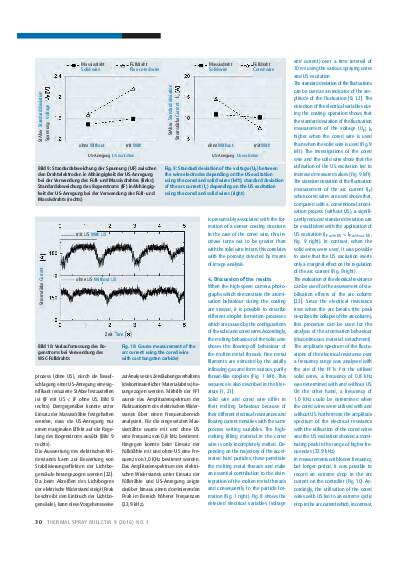

Arc spraying constitutes an established process for the application of wear and corrosion protection coatings. During arc spraying, the particles are formed from the molten pool at the tips of the wire electrodes due to the injection of an atomiser gas. The particle characteristics mainly depend on the melting and atomisation behaviour of the wires. Accordingly, the molten particles form a lamellar coating when they splash on the substrate. A finely structured lamellar coating composition may consequently lead to improved tribological and mechanical coating properties. This investigation introduces the utilisation of excitation by means of ultrasound (US) in the region of the wire guide rollers for the production of finely structured wear protection coatings. Various parameter studies are conducted using an iron-based alloy in the form of a solid wire and a cored wire. Particle diagnostics are used in order to analyse the atomisation behaviour. The electrical variables such as voltage and current are detected and evaluated in process monitoring. The coating systems produced with the aid of the US excitation are investigated metallographically and are compared with the coating structure manufactured using conventional process parameters.

Pages: 24 - 32

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription