Manufacture of composite diamond/metal coatingsusing thermal spraying procedures

Authors: Prof. Dr.-Ing. Dipl.-Wirt.Ing. Wolfgang Tillmann, M. Sc. Alexander Brinkhoff, M. Sc. Christopher Schaak

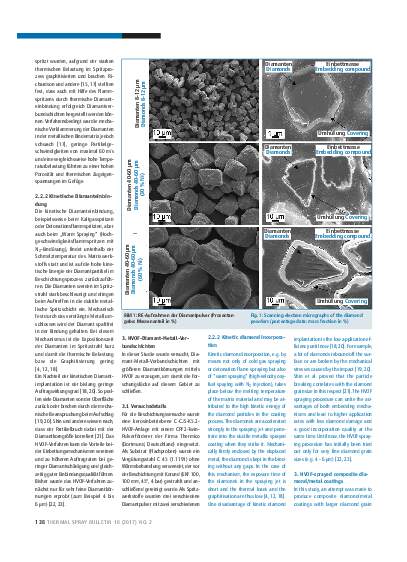

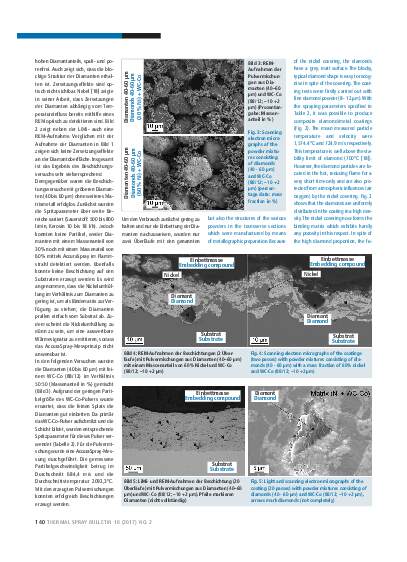

Diamond is the hardest known material and therefore generates continuous interest in applications with the highest stresses in the various industrial sectors. Because of the prices of natural diamonds, synthetic diamonds are used on an industrial scale. Moreover, there is the possibility of depositing diamond-like coatings using various coating techniques (electrochemical or autocatalytic coating procedures as well as chemical or physical vapour deposition). Until now, the thermal spraying procedures have led a niche existence for the manufacture of diamond-reinforced coatings. In this respect, these offer a few advantages: Composite diamond/metal coatings can be produced over large areas and close to the final contours in atmospheric conditions. Depending on the utilised procedures, various diamond grain sizes can be processed and the composite diamond/metal coatings designed corresponding to the application. Depending on the procedure, a distinction is made between thermal and kinetic diamond incorporation. The present article gives an insight into the synthesis of diamonds, the techniques for producing diamond-like coatings as well as the state of the art in the field of the thermal spraying of diamonds and the production of composite diamond/metal coatings. Corresponding results from our own research activities are introduced

in this respect.

Pages: 136 - 142

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription