HVOF DIATURB coatings on the basis oftungsten carbide, cobalt and chromium forutilisation in hydroelectric power

Authors: Dr.-Ing. Axel Kratzsch, Dipl.-Ing. Daniel Christ, Ing. Josef Seidl

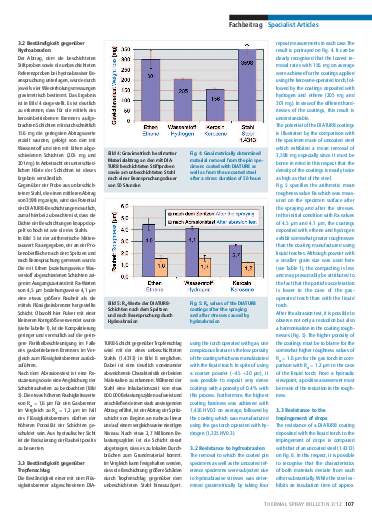

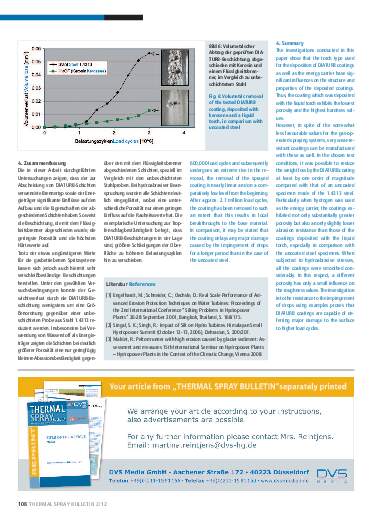

DIATURB coatings which are based on tungsten carbide, cobalt and chromium and are deposited using HVOF processes have been established as protection against hydroabrasive wear in the field of hydroelectric power for many years [1]. In this respect, HVOF spraying systems operated with liquid fuels are characterised by high application rates and the good economic viability associated with these. One increasing trend is the

demand of the market to also coating more complex geometries whose surfaces are more difficult to reach for the HVOF coating process. For example, Pelton buckets with smaller dimensions can no longer be coated with kerosene-operated torch systems because of the cramped space conditions. Gas-operated spraying

systems with smaller dimensions offer advantages here. Within the framework of this paper, DIATURB coatings were applied with various HVOF torch systems and energy carriers and were characterised with regard to their structure and properties. In this case, the objective was to investigate what influence the

utilised torch system and the energy carrier have on the quality of a coating.

Pages: 104 - 108

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription