Cold gas spraying of zinc and zinc alloy coatingsfor printing applications

Authors: M. Sc. Eng. Kouichiro Onizawa, Dipl.-Ing. Matthias Schulze, Dr. Frank Gärtner, Prof. Dr. Thomas Klassen

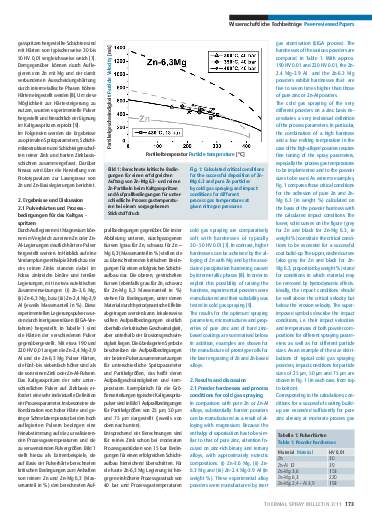

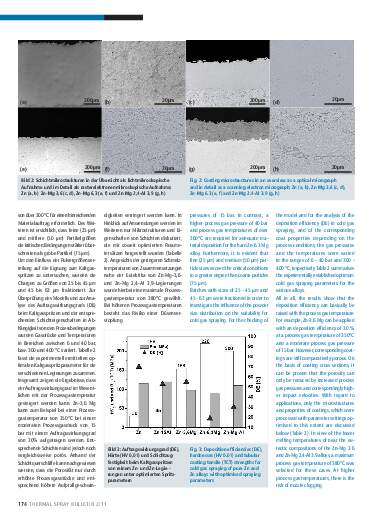

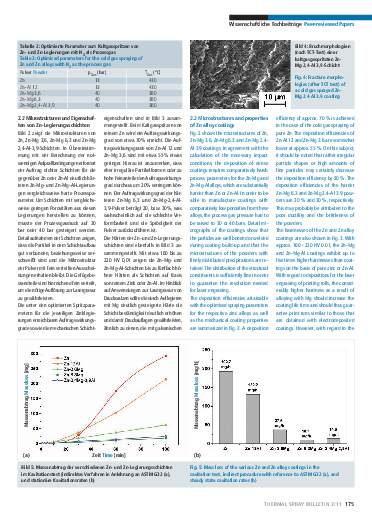

During cold gas spraying, the spraying material and the component are exposed to only comparatively moderate temperatures. Thus, the process is suitable, in particular, for oxidation-sensitive materials such as zinc alloys, which have recently also been used for applications in the field of the laser engraving of printing rolls. The spectrum from the soft pure zinc powder to the precipitationhardened alloy powders necessitates the individual fine tuning of the cold gas spraying parameters. Corresponding coating microstructures are dense and, with respect to hardness, wear resistance and corrosion resistance, the coatings show similar properties as comparable bulk materials. Tests with printing roll specimens show that cold-gas-sprayed pure zinc and also zinc alloy coatings are suitable for laser engraving.

Pages: 172 - 178

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription