Capability of blue lasers for cladding of noble metals

Authors: Dr.-Ing. Andreas Wank, M. Eng. Alexander Hitzek, M. Eng. Christian Schmengler, Dr.-Ing. Thomas Molitor, Dr.-Ing. Dipl.-Wirt.-Ing. Sörn Ocylok

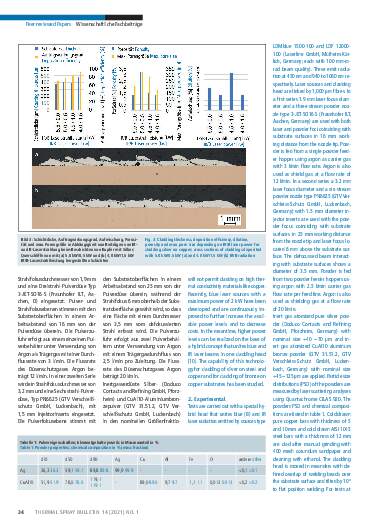

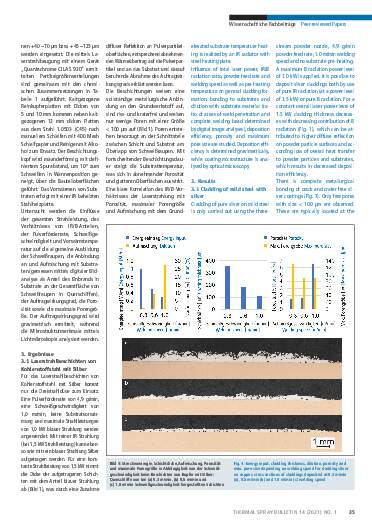

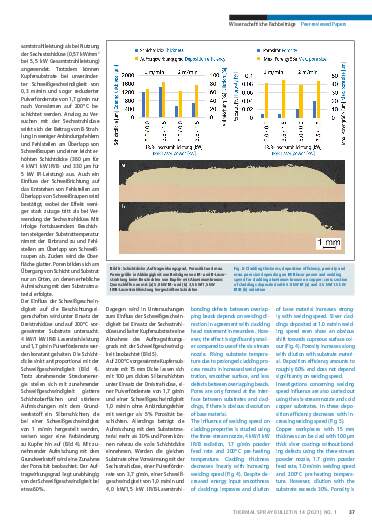

These days mostly IR or infrared laser sources are used in industrial laser cladding applications. The absorption of such radiation is particularly low for noble metals like copper or silver in solid state. Also, noble metals high thermal conductivity results in strong heat flux into respective substrates. Blue lasers emitting at 450 nm wavelength are promising tools for cladding of noble metals, because absorption is about one order of magnitude higher compared to IR lasers. The effect of use of blue lasers has been examined for cladding of aluminium bronze and silver on copper and for cladding of silver on mild steel. Besides pure blue and pure IR laser radiation also combinations are applied. Weld penetration, dilution with base material and porosity are analysed by metallographic inspection of cross sections and deposition efficiency is also studied. Contribution of blue laser radiation generally permits improved deposition efficiency for the tested combinations of cladding and substrate materials. Without contribution of B or blue laser radiation silver could not be clad on copper substrates consistently without pre-heating even at laser power of 5 kW but use of blue laser radiation permits production of smooth, gas tight claddings without bonding defects. For cladding of silver on mild steel blue lasers permit particularly homogeneous weld penetration and high deposition efficiency.

Pages: 32 - 39

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription