Arc spraying in silane-doped argon: Widening the material spectrum in oxygen-free process zones

Peer-reviewed Papers

Authors:

Dipl.-Ing. Manuel Rodriguez Diaz,

Maik Szafarska,

René Gustus,

Prof. Dr.-Ing. habil. Kai Möhwald,

Prof. Dr.-Ing. Hans Jürgen Maier

DOI:

https://doi.org/10.53192/TSB20240156

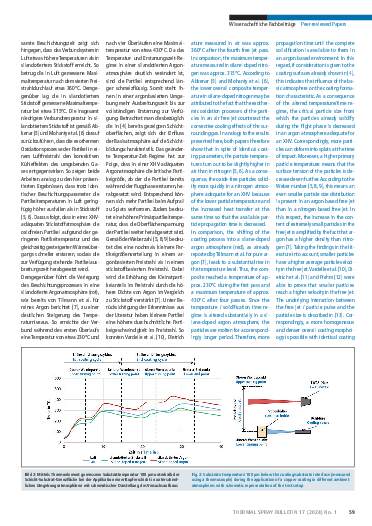

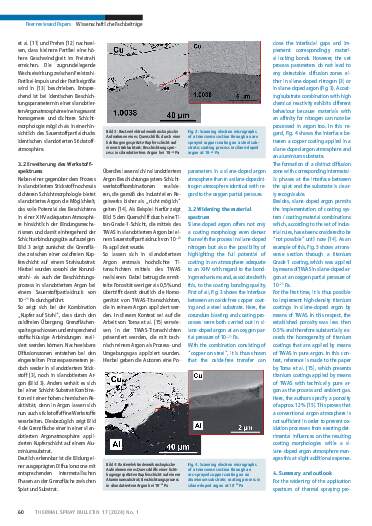

The oxygen present in the process zone of thermal spraying causes the oxidation of the respective interfaces and the surfaces of a thermally sprayed composite and exerts crucial influences on the functional properties and bonding quality of the coating. Previous papers introduced an innovative coating strategy with which a thermal coating process can be transfered into a nearly oxygen-free environment. The use of a monosilane/nitrogen mixture made it possible to implement oxide- free copper coatings with high adhesive pull strengths. One of the previous papers dealt with the influences of various inert gas mixtures with different residual oxygen proportions on the arc and the particle atomisation in the case of twin-wire arc spraying. In the present paper, it is investigated what influences the utilised atmosphere has on the coating and bonding properties. Specifically, it is shown that a silane-doped argon atmosphere whose residual oxygen content corresponds to that of an extremely high vacuum at ambient pressure gives rise to temperature / solidification time regimes that permit large-area diffusion bonds between the coating and the substrate. Furthermore, the example of titanium demonstrates that innovative coating morphologies can now be implemented.

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.