Mechanical and tribological properties of HVOFsprayedceramic coatings

Authors: Dr. Giovanni Bolelli, Dr. Luca Lusvarghi, Dr. Simo-Pekka Hannula, Dr. Erja Turunen, Tommi Varis

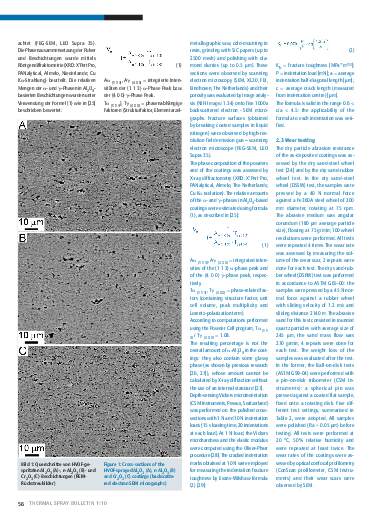

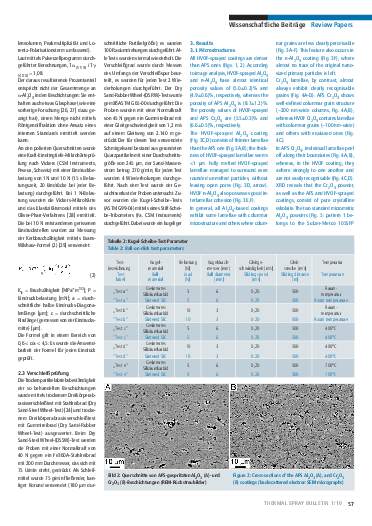

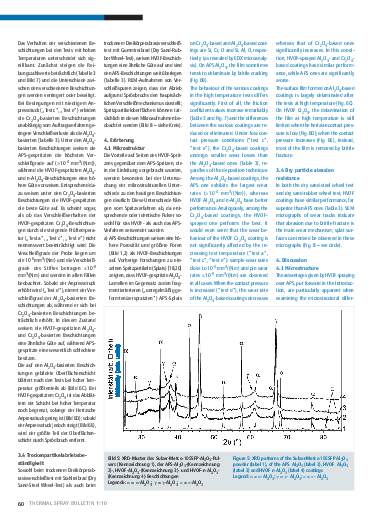

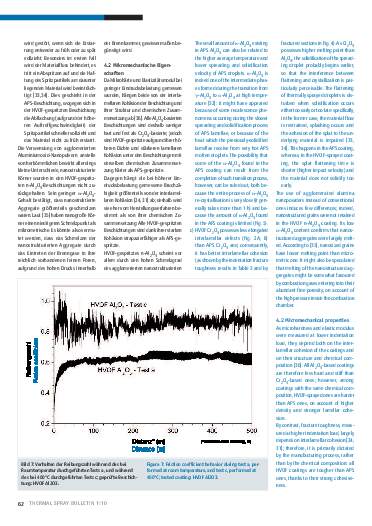

Al2O3 and Cr2O3 coatings deposited onto steel by high velocity oxygen-fuel (HVOF) spraying were compared to conventional atmospheric plasma sprayed (APS) coatings. HVOF-sprayed coatings exhibit lower porosity than APS coatings and possess higher Vickers microhardness, indentation fracture toughness and elastic modulus. During ball-on-disk tests against SiC at room temperature and at low normal load, all coatings develop stable tribofilms and undergo mild wear (<10-6 mm3/(Nm)); at higher temperature and/or normal load, brittle fracture wear prevails. Under these latter conditions, HVOF coatings become superior to APS coatings, thanks to their higher toughness. Analogously, in dry particle abrasion, where brittle fracture prevails, HVOF coatings outperform APS coatings.

Pages: 54 - 67

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription