Online process monitoring during the HVOF ID process

Peer-reviewed Papers

Authors:

Prof. Dr.-Ing. Dipl.-Wirt.Ing. Wolfgang Tillmann,

Prof. Dr. Jochen Schein,

Dr.-Ing. Stephan Zimmermann,

Ahmad Said,

Dr.-Ing. Ingor Theodor Baumann,

Dipl.-Ing. Manuel Pinho Ferreira,

Dipl.-Wirt.-Ing. Leif Gereon Hagen

DOI:

https://doi.org/10.53192/TSB202402116

The ID-coating of components using highly kinetic thermal spraying procedures such as high-velocity oxy-fuel (HVOF) spraying is becoming ever more significant in science and industry. In order to permit a ID-coating process which is not only stable but also efficient and, at the same time, to be able to produce ID-coatings with excellent quality properties, decisive significance is attached to process diagnostics. However, because the ID-coating conditions change in comparison with conventional coating, there has, until now, been a lack of suitable systems and stategies in the ID-coating sector (internal diameter- ID). For this reason, this article presents initial approaches to the implementation of online process diagnostics for the HVOF ID-coating process

which have been elaborated in the course of the joint IGF project 01IF22830N. In a first step, this encompasses the development and setting- up of suitable measuring optics with deflection mirrors and adapters as well as test objects with optimised

accesses for the diagnostics (aluminium tube to be lined with an ID of 120 mm and glass viewing windows). In order to be able to estimate the temperature distribution in the ID component,

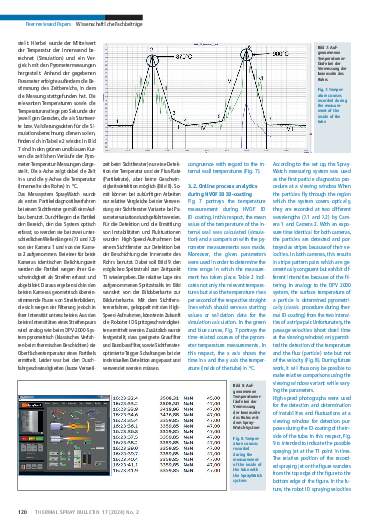

CFD simulations were carried out with the actual pyrometer measurements of the internal wall for the specified ID process. The measurements during the HVOFID-coating process were taken with the Spray- Watch system and a high-speed camera system in order to obtain particle flight properties in this way.

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.