Optimisation of the hard material fractions offlux-cored wires with large diameters for arc wirecoating

Authors: Dr.-Ing Ruben Winkler, Dipl.-Ing. Gerd Paczkowski, Prof. Dr.-Ing. habil. Thomas Lampke

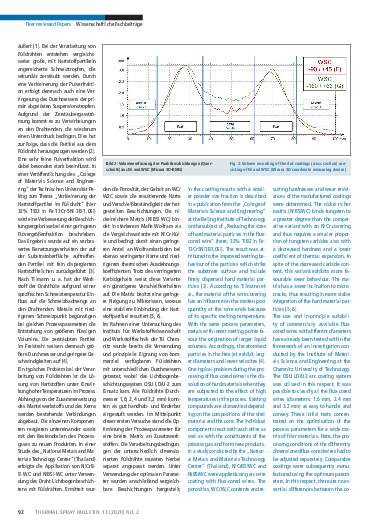

One strategy for the manufacture of wear-resistant coatings consists of embedding carbidic hard material particles in a certain size and concentration into a ductile matrix. Using arc wire coating, flux-cored wires with metallic coverings and particle-filled cores are utilised for this purpose. Until now, inadequate investigations have been conducted into the process for flux-cored wires with large diameters (> 1.6 mm). The high kinetics of the arc and the gas flow entail substantial challenges in relation to the reproducibility, the homogeneity and the material efficiency. As a basis for a considerably improved understanding of the operation, an investigation was conducted into the connections between the wire design, the particle size and the hard material transfer. The investigation subject related to flux-cored wires with nickel shells and tungsten carbide as the particle filling. On the basis of dot coatings, it was possible to establish an increased probability of the embedding of hard materials with small diameters (< 100 μm).

Pages: 90 - 96

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription