Optimization of the carbide grain size in WC-Co(Cr)-coatings for increase of the wear resistance with simultaneous corrosive load

Peer-reviewed Papers

Authors:

Dipl.-Ing. Gerd Paczkowski,

Prof. Dr.-Ing. habil. Thomas Lampke,

Dr. Susan Conze,

Dr.-Ing. Johannes Pötschke,

Dr.-Ing. Lutz-Michael Berger

DOI:

https://doi.org/10.53192/TSB20220294

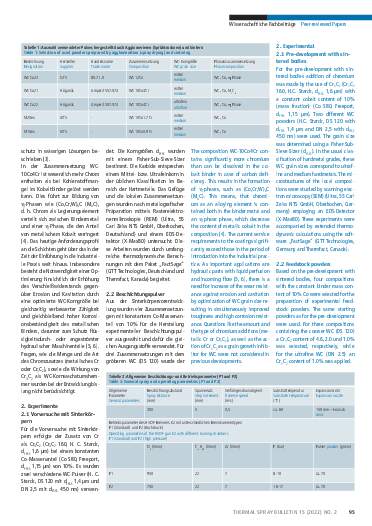

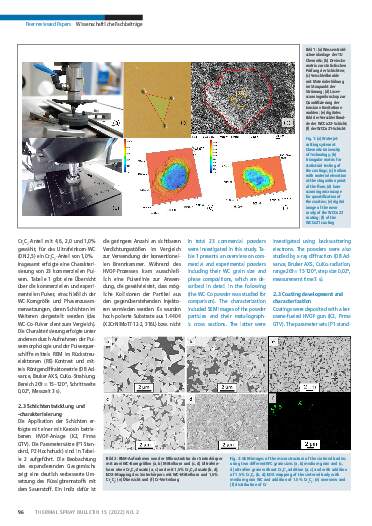

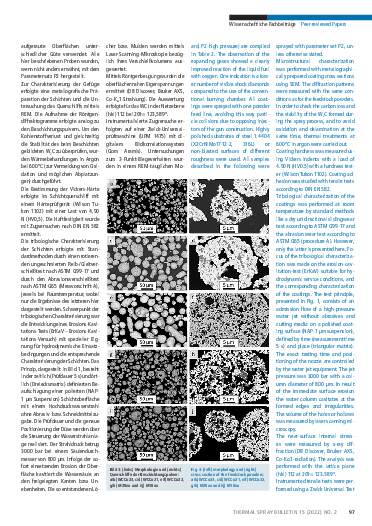

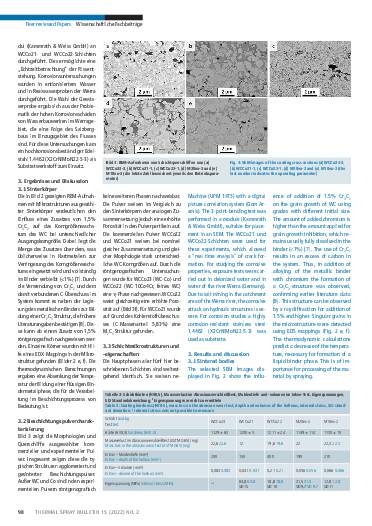

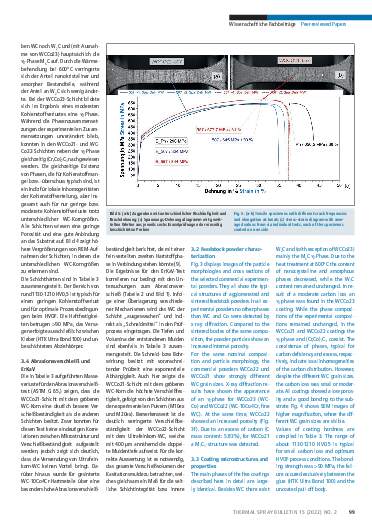

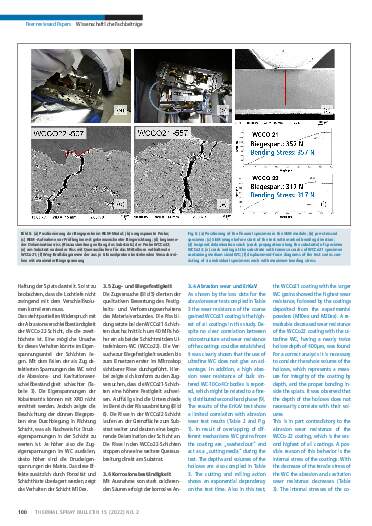

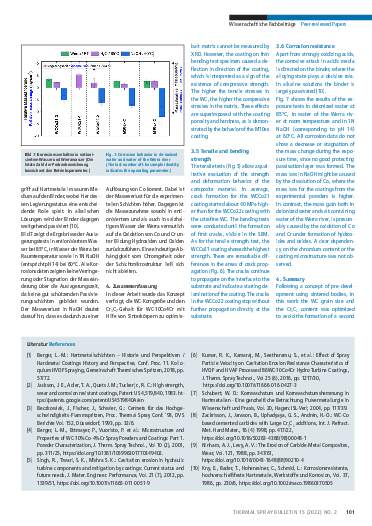

The aim of the work presented in this paper was the adaptation of well-established WC-10Co4Cr coatings to changed service requirements. As important applications are hydraulic parts with liquid perfusion and incoming flow, there is a need for increase of the wear resistance against erosion and cavitation by optimization of WC grain size resulting in simultaneously improved toughness and high corrosion resistance. For this purpose, the Cr3C2 content plays a decisive role. A decrease of the Cr3C2 content compared to the standard composition was evaluated applying a pre-development with sintered bodies and the preparation of experimental feedstock powders. A liquid-fueled HVOF process was used for the application of these powders as well as commercially available powders having representative structures. This publication describes the results of the material development and selected coating properties. A new test method (ErKaV) is presented, which allows an evaluation of the tribological properties using highly erosive and cavitative test conditions.

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.