Optimisation of the spray parameters tocoat valve shafts by employing fine Cr3C2-25NiCrpowder in the HVOF spray process

Peer-reviewed Papers

Authors:

Prof. Dr.-Ing. Dipl.-Wirt.Ing. Wolfgang Tillmann,

Dipl.-Ing. Weifeng Luo,

Dr.-Ing. Ingor Theodor Baumann,

Prof. Dr. Zezhou Feng,

B. Eng. Yaping Ji,

M. Eng. Yanling Feng

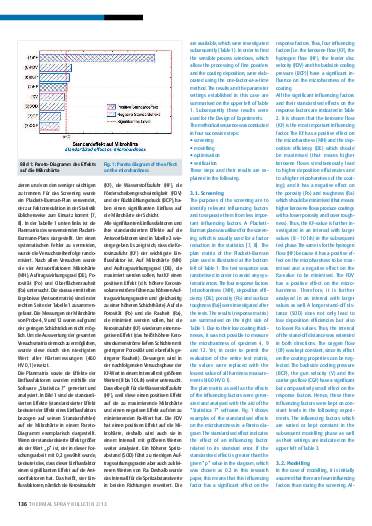

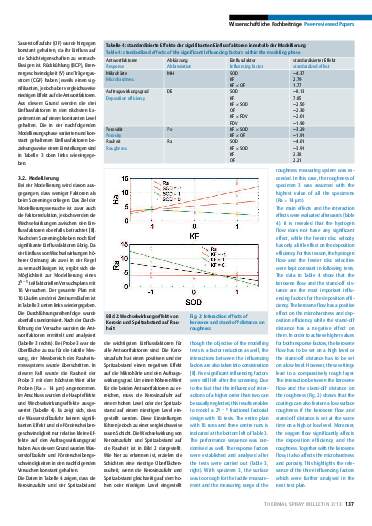

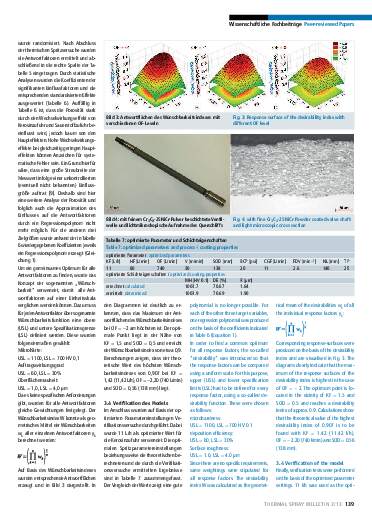

In order to extend the service life of valve shafts for steam turbines in the power station industry, shafts were provided with a hard material coating within the framework of a cooperation project between the TU Dortmund University and the China Academy of Machinery Science & Technology. For this purpose, a fine Cr3C2-25NiCr powder was employed in the High Velocity Oxygen Fuel flame spraying process. Because of the lower specific weight and the high surface energy, the fine powder was not only difficult to process by means of spray technology but also hard to transport into the feeding system. In order to process the fine powder, the parameters were optimised using the Design of Experiments. After the optimisation phase, it was possible to produce nearly dense, finely structured coatings (porosity: < 1 %) with a high microhardness of 1,004 HV 0.1, a low roughness of Ra = 1.9 µm and a high deposition efficiency of 71 %. Following the parameter study, the hard material coatings were deposited on valve shafts and the utilisation behaviour of the coated components was evaluated.

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.