Industrial Optimization and Efficiency forProcessing of HVOF

Authors: S. M. Ang, Assoc. Prof. Scott Wade, Howse Hugo, Prof. Christopher C. Berndt

Optimising the efficiency of the thermal spray process is critical in industrial environments

where high production rates that are linked to excellent quality

control must be exploited. In this study, in-flight spray diagnostics have been

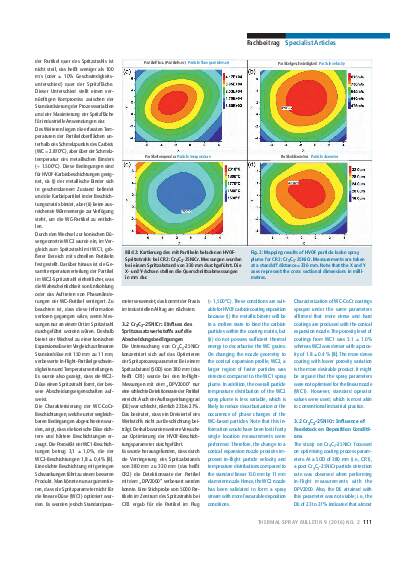

employed to monitor the spray deposition of WC-10Co-4Cr and Cr3C2-25NiCr

feedstocks (Oerlikon Metco AG, Switzerland) using a kerosene fuelled system

(GTV HVOF K2, GTV Verschleißschutz GmbH, Germany). Two HVOF barrels, either

of straight or conical internal bore, were employed with the goal of controlling

the spray footprint geometry as well as maintaining consistent temperature and

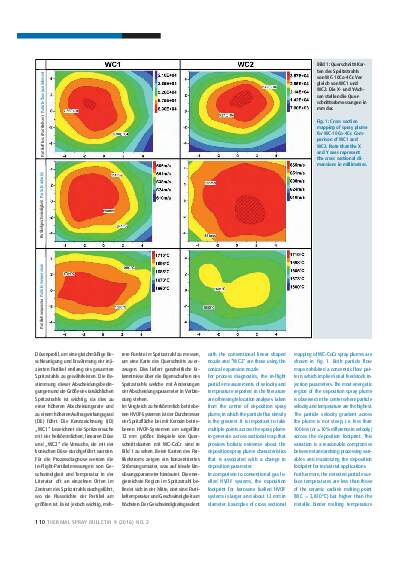

velocity conditions. The spray plume mapping (DPV2000, Tecnar Automation

Ltd., Quebec, Canada) highlights that the conical expansion nozzle allows

formation of a spray stream with more favourable deposition dynamics. Additionally

the optimum thermal spray stand off distance could be objectively determined,

as well as breakup of the composite feedstock monitored.

Pages: 108 - 113

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription