Structuring of steel specimens in order to raise theadhesive strength of a thermally sprayed copper-basedalloy for the investigation of the utilisation potentialson connecting rods without any bearing shells

Authors: Dipl.-Ing. Daniel Stehle, Prof. Dipl.-Ing. Dr.techn. Friedrich Bleicher, Dipl.-Ing. Dr.techn. Alois Schmid, Dipl.-Ing. Thomas Flatz

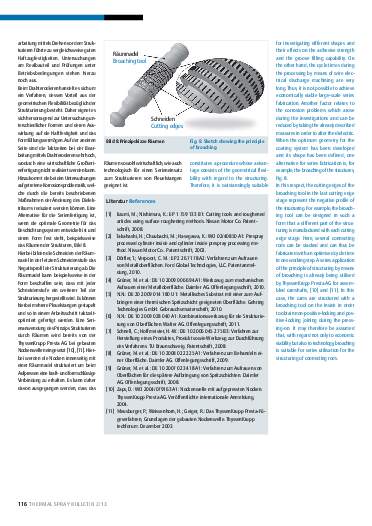

This article deals with mechanical structuring by means of wire electrical discharge machining in order to produce undercut structures which are intended to raise the adhesive strength of a copper coating on a steel substrate. The investigations were conducted on steel specimens which were coated with a copperbased alloy in a conventional arc wire spraying (AWS) process. The processes generated on the test specimens are subsequently to be transferred to connecting rods, with the objective of replacing the half-shells of the sliding bearings in the connecting rod big end with a thermally sprayed bearing coating.

Pages: 110 - 116

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription