Thermal sprayed coatings as a solution for joining steel/Al composite castings

Authors: Prof. Dr.-Ing. Kirsten Bobzin, M. Sc. Hendrik Heinemann, M. Sc. Marvin Erck, B. Sc. Johannes Körner

DOI: https://doi.org/10.53192/TSB20230298

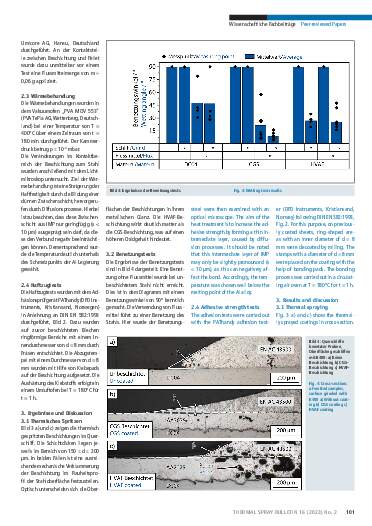

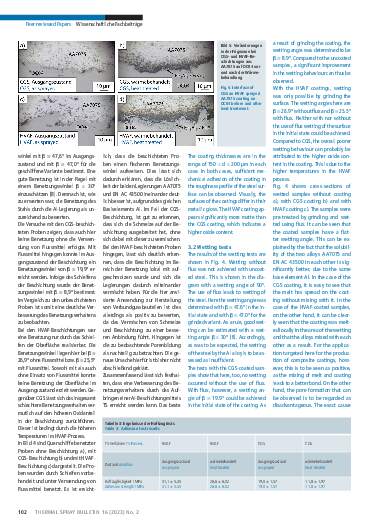

Material composites made of aluminium die cast and steel offer great potential for lightweight construction applications. The control of intermetallic phases, which arise due to diffusion processes, is particularly challenging. These influence the technological properties in the composite and hinder the joining process. To realise these composites, a thermally sprayed coating using the Al alloy AA7075 as an bonding layer was applied to a steel substrate by means of cold gas spraying and

HVAF. This is intended to prevent direct contact between the molten Al and the steel and to prevent the diffusion of elements into the steel. The interaction of the coatings with an Al melt was investigated, whereby different post-treatments of the coating were considered to optimise the wetting behaviour. Furthermore, the influence of a specific heat treatment on the adhesive strength was investigated. It was shown that both mechanical post-treatment of the coating and the use of a flux have a favourable effect on the wettability. An additional heat treatment, on the other hand, proved to be disadvantageous. The results presented in the article contribute to the possibility of producing composite cast components with increased quality and strength in the future.

Pages: 98 - 104

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription