Thermal spraying in silane-doped shielding gases: A new approach for innovative coatings in con-trolled process atmospheres

Authors: Dipl.-Ing. Manuel Rodriguez Diaz, Dr. rer. nat. Martin Nicolaus, Prof. Dr.-Ing. habil. Kai Möhwald, Prof. Dr.-Ing. Hans Jürgen Maier

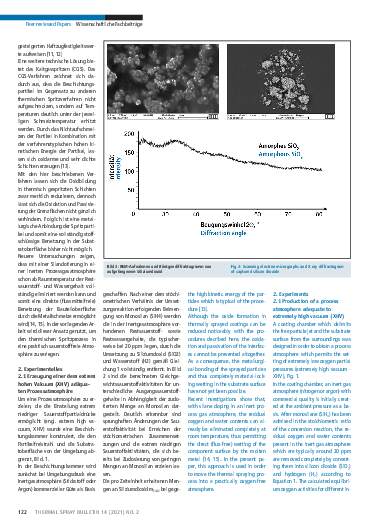

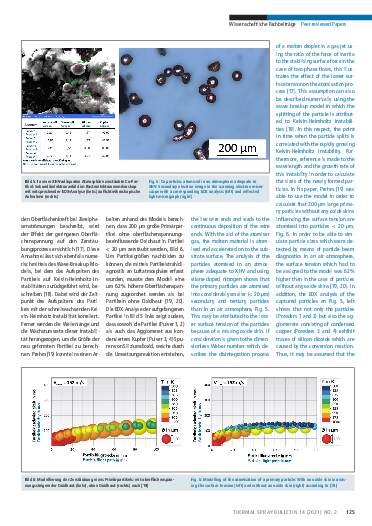

In addition to the actual function-al properties, the bond strengths between the coating and the substrate constitute one of the decisive quality characteristics of a thermally sprayed coating. Since conventional thermal spraying is carried out almost exclusively in an air at-mosphere, this leads to the oxida-tion of the surfaces and the interfaces at the coating point so that no material-locking interfaces can be achieved. The present paper shows that it is possible to carry out a thermal spraying process in a mixture consisting of monosilane and an inert gas. Using the example of arc-sprayed copper coatings, it is demonstrated that the extremely low oxygen partial pressures aris-ing in this ambient medium lead to coatings without any oxide borders and the coating porosity can also be reduced considerably.

Pages: 120 - 127

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription