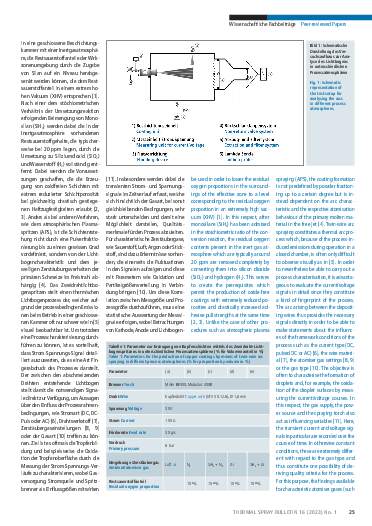

Thermal spraying in oxygen-free environment: Meltoff and atomisation behaviour of twin-wire arc spraying processes in silane-doped inert gases

Peer-reviewed Papers

Authors:

Dipl.-Ing. Manuel Rodriguez Diaz,

Dr.-Ing. Thomas Hassel,

Lennart Vincent Hölscher,

Maik Szafarska,

René Gustus,

Prof. Dr.-Ing. habil. Kai Möhwald,

Prof. Dr.-Ing. Hans Jürgen Maier

DOI:

https://doi.org/10.53192/TSB20230124

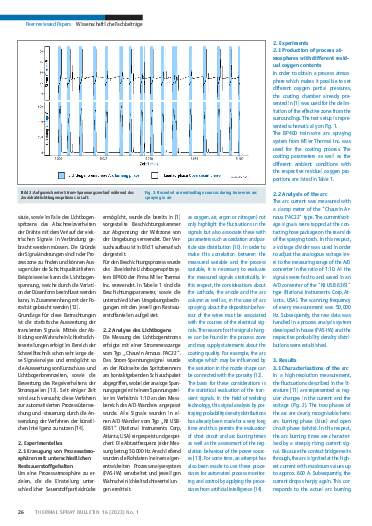

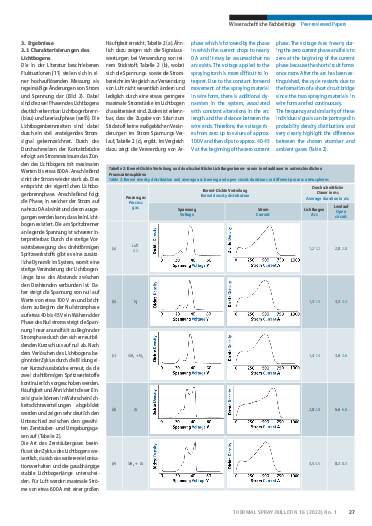

In addition to the actual functional properties, the bond strengths between the coating and the substrate

constitute one of the decisive quality criteria of a thermally sprayed coating. Since conventional thermal

spraying is carried out almost exclusively in an air atmosphere, this leads to the oxidation of the surfaces

and the interfaces at the coating point so that no material-locking interfaces can be achieved. One possibility

of completely suppressing the oxidation during the coating operation is offered by shifting the coating

operation into a monosilane / inert gas mixture. The present paper deals with the influences of different inert

gas mixtures with different residual oxygen proportions on the arc and the particle atomisation in the case

of twin-wire arc spraying. It is shown that the shifting of the coating process into a silane-doped inert gas atmosphere leads to freedom from oxides and a rise in the productivity of the process.

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.