Overview of high entropy oxides as potential solutions for turbine applications

Authors: Dr. Timothy Sharobem, M. Sc. Jonathan Gutleber, Dr. Gopal Dwivedi, Chris Dambra

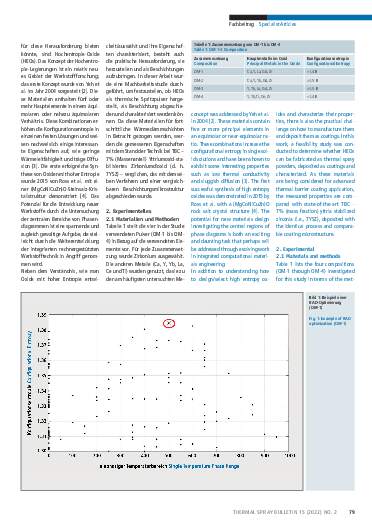

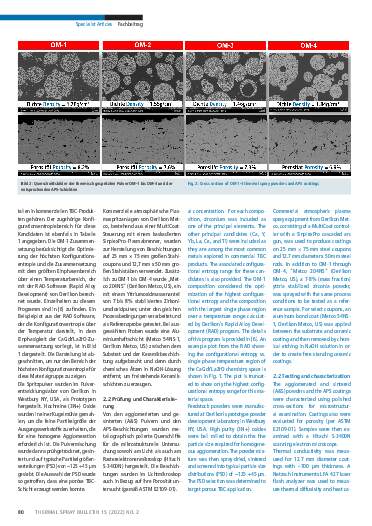

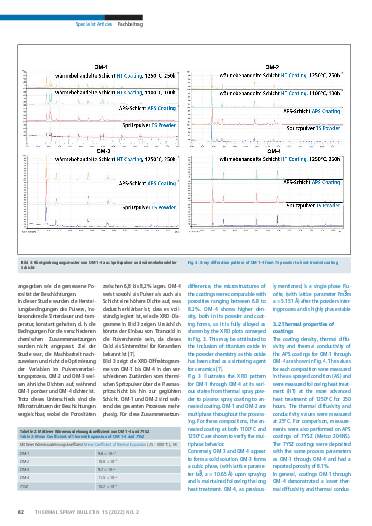

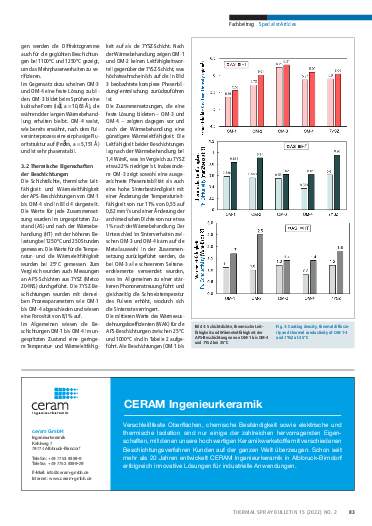

Higher operating temperatures within turbine engines present an opportunity for novel material design for thermal barrier coatings to provide advanced properties such as low thermal conductivity and phase stability. One potential area for material development is high entropy alloys. This class of materials, which consists of five or more principal elements, has been cited since the early 2000s for unique properties which have been attributed to the highly strained lattice structures. With recent advancements in computational materials design, these materials can be explored even further, particularly for applications such as turbine coatings. One aspect however which has been rarely discussed is the feasibility to manufacture high entropy oxides and deposit them as thermal spray coatings. In this study, four material compositions (OM-1

through OM-4) were manufactured using conventional ceramic thermal spray powder production methods and were deposited via atmospheric plasma spray. Two of the coating materials OM-3 and OM-4, demonstrated a single phase crystal structure after plasma spray deposition and exhibited discernibly reduced thermal diffusivity compared to 7YSZ. These coatings also show strong phase stability after heat treatment at 250 hours at 1250°C.

Pages: 78 - 85

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription