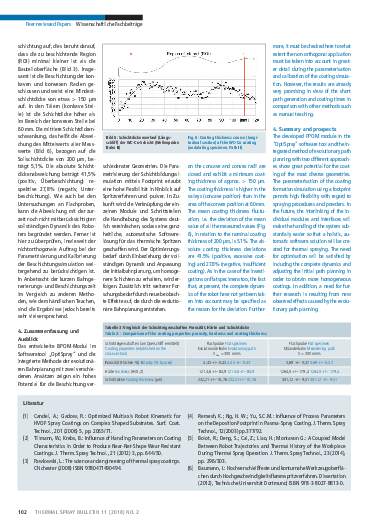

Investigation into the properties of HVOF-sprayedWC-Co coatings on plane and complex surfaces,manufactured with an evolution-based path planningmethod

Peer-reviewed Papers

Authors:

Prof. Dr.-Ing. Dipl.-Wirt.Ing. Wolfgang Tillmann,

M. Sc. Christopher Schaak,

M. Sc. Jonas Zajaczkowski,

Prof. Dr. Heinrich Müller,

Dr. Daniel Hegels,

Dipl.-Inform. Marcel Gaspar,

Prof. Dr.-Ing. Bernd Kuhlenkötter,

M. Sc. Denis Daniel Störkle

In spite of the fact that robot technology is available in many cases, automated path planning and optimisation methods (PPOMs) for thermal spraying processes have only restricted applications in industrial practice, particularly at small and medium-sized enterprises (SMEs). Many different software-supported partial solutions exist for the entire fabrication process from the CAD data to the finish-coated component. A new automatic path planning approach based on evolutionary movement paths is being pursued within the framework of the development of a holistic solution approach in the project entitled “Development of a software tool (OptiSpray) for automated path production, movement optimisation and coating formation simulation in the case of robot-assisted thermal spraying”. Classic meandering paths which are “taught” or created offline are not expedient for the near-net-shape coating of complex geometries and are not the most effective solution even for a simple, flat standard geometry. On the other hand, movement paths which are created on the basis of evolution and are subsequently optimised using coating formation simulations may lead to uniform coating results and, while doing so, minimise the thermal loads and the overspray.

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.