Investigation of influencing factors on the transferof wire arc sprayed Zn coatings for the metallisationof plastics parts

Authors: Prof. Dr.-Ing. Kirsten Bobzin, Dr.-Ing. Martin Andreas Knoch, M. Sc. Xifang Liao, Prof. Dr.-Ing. Christian Hopmann, M. Sc. Philipp Ochotta

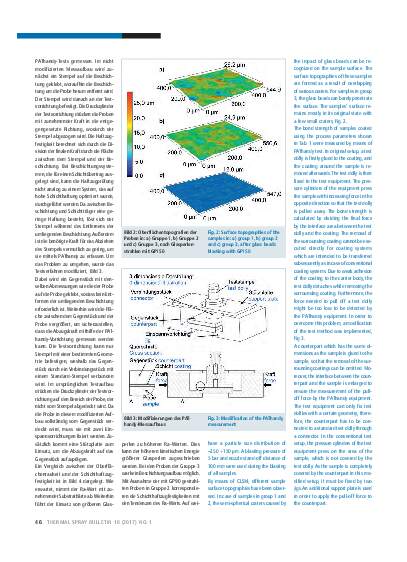

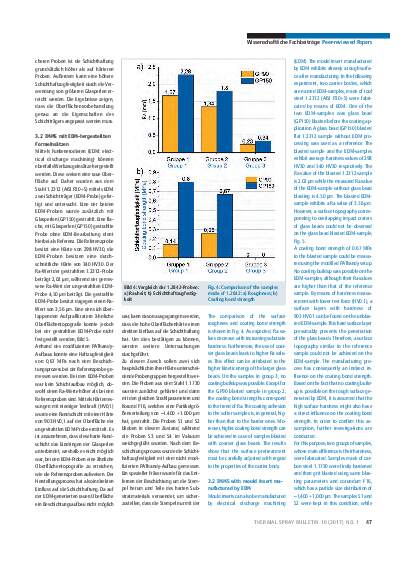

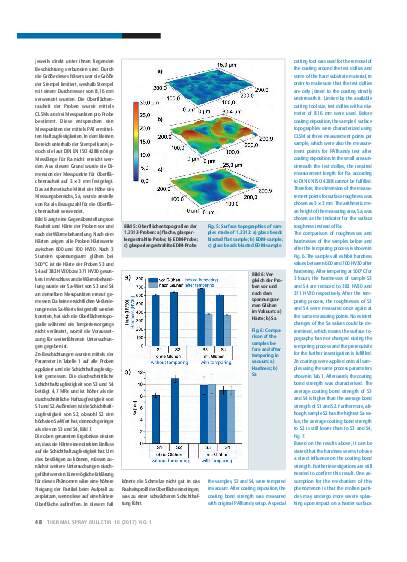

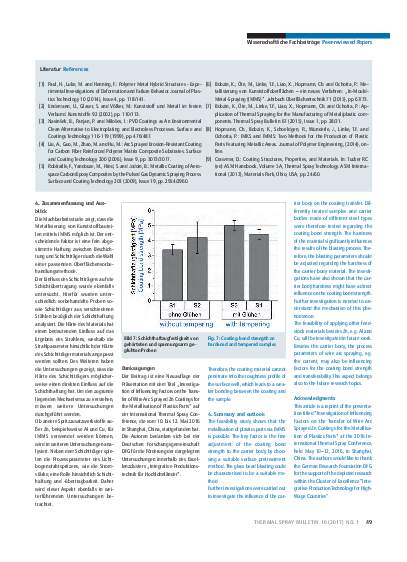

In a current study, a new approach for the efficient production of metallised plastics parts, the so called In-Mould-Metal-Spraying (IMMS), is being developed. A Zn coating is at first thermally sprayed onto mould cavity inserts (carrier body) using wire arc spraying and subsequently transferred onto a plastics carrier via injection moulding. Among others, a finely adjusted bond strength between carrier body and coating is essential for a successful coating transfer. The influence of the carrier body and the surface pretreatment on the bond strength at the coating/carrier body interface and subsequently on the transferability of the coatings was investigated.

Pages: 43 - 49

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription