Characterisation of thermally applied metallic materialsfor numerical calculations

Authors: Dr.-Ing Ruben Winkler, Dipl.-Ing. Erik Saborowski, Dipl.-Ing. Gerd Paczkowski, Prof. Dr.-Ing. habil. Thomas Lampke

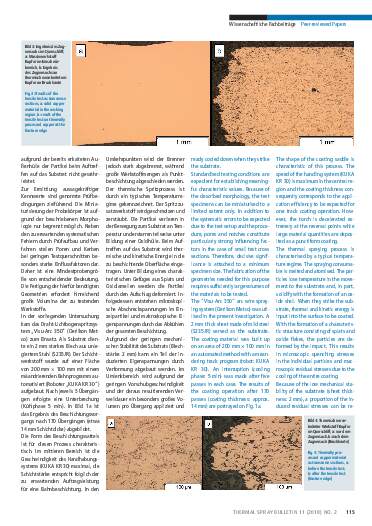

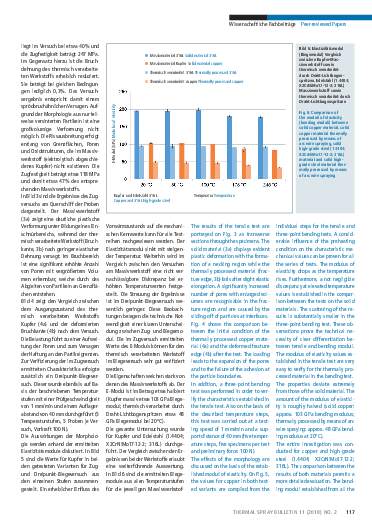

The objective of the IGF Project No. 19.102 B promoted by AiF consists of the characterisation of thermally applied metallic materials (Cu 98.7; X2CrNi-Mo17-12-2) by recording their mechanical properties. The obtained data is to be implemented in existing models for commercial FE software in order to be able to portray cooling and deformation processes during thermal coating. For this purpose, test specimens made of copper and high-grade steel were manufactured using arc wire spraying. The resulting volume was processed further into corresponding test pieces by means of electrical discharge machining. In order to be able to assess those differences in the material properties which are caused by the thermal spraying process, reference specimens were also manufactured from the respective solid materials. The characteristic values were recorded using tensile and bending tests in a temperature range from 20°C to 245°C.

Pages: 112 - 118

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription