The effect of the hardness and sandblasting on theobtained residual stresses in 100Cr6 and the obtainedHVOF-coatings

Authors: Prof. Dr.-Ing. Dipl.-Wirt.Ing. Wolfgang Tillmann, Dipl.-Ing. Mohamed Abdulgader, B. Sc. Steffen Hüning

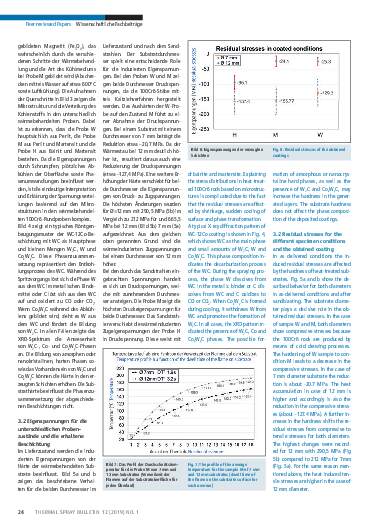

Residual stresses are an inherent feature of the thermal spraying processes. The induced stresses affect the coating microstructure and performance directly. In the present work, the effect of the residual stresses in the substrate surface on the microstructure and performance of the obtained coating were investigated. The residual stresses are induced in the substrate surface as a result of heat treatment and sandblasting. Furthermore, the flame temperature and the high-velocity in-flight particles lead to the formation of residual stresses in the obtained coatings. The heat treatment of the cold drawn bearing steel 100Cr6 shifts the stresses towards increased residual tensile stress. The sandblasting of the hardened 100Cr6 leads to the development of residual compressive stresses. Their magnitude depends on the hardness level of the sandblasted surface. The dwell time of the spray flame on the substrate surface leads to a depletion of the induced compressive stresses. However, the induced residual stresses do not affect the phase composition

of the produced coatings. However, they show a minor impact on the wear resistance of the obtained coatings.

Pages: 20 - 27

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription