Influence of nozzle geometry and impact parameterson microstructure and properties of kinetically sprayed titanium, TiAl6V4 and molybdenum coatings

Authors: Dipl.-Wi.-Ing. Kurt Binder, Dr. Frank Gärtner, Prof. Dr. Thomas Klassen

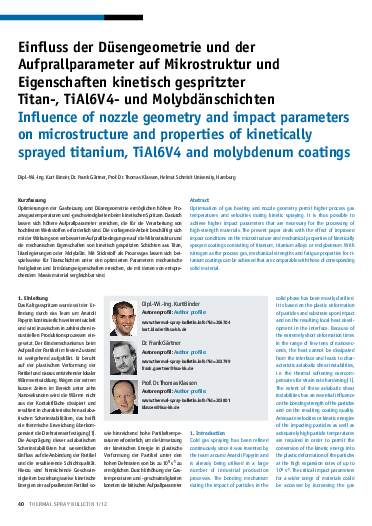

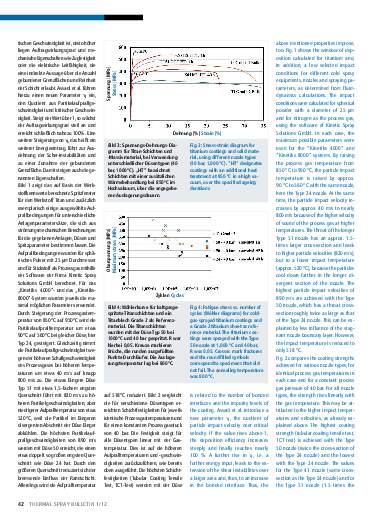

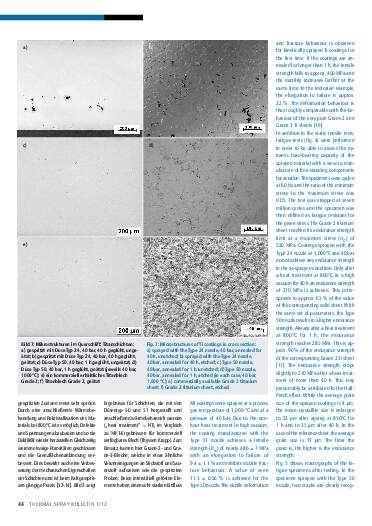

Optimisation of gas heating and nozzle geometry permit higher process gas temperatures and velocities during kinetic spraying. It is thus possible to achieve higher impact parameters that are necessary for the processing of high-strength materials. The present paper deals with the effect of improved impact conditions on the microstructure and mechanical properties of kinetically sprayed coatings consisting of titanium, titanium alloys or molybdenum. With nitrogen as the process gas, mechanical strengths and fatigue properties for titanium coatings can be achieved that are comparable with those of corresponding solid material.

Pages: 40 - 46

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription