Coats which contain hard Materials and are appliedby Means of Arc Spraying

Authors: Prof. Dr.-Ing. Dipl.-Wirt.Ing. Wolfgang Tillmann, Dr.-Ing. habil. Evelina Vogli, Dipl.-Phys. Ing. Benjamin Krebs, Dipl.-Ing. Mohamed Abdulgader

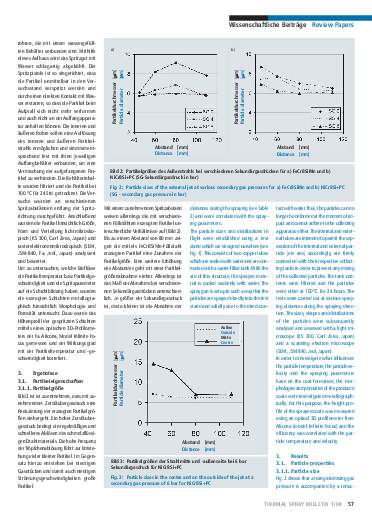

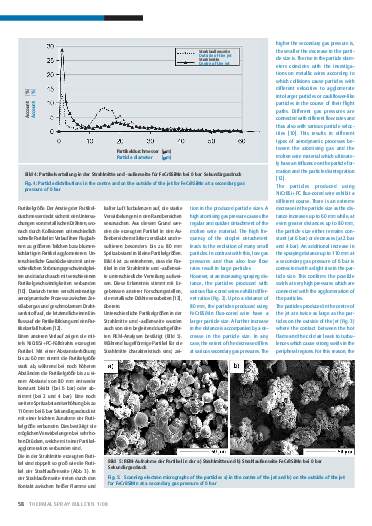

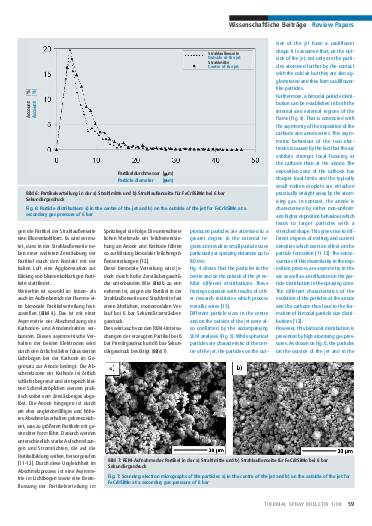

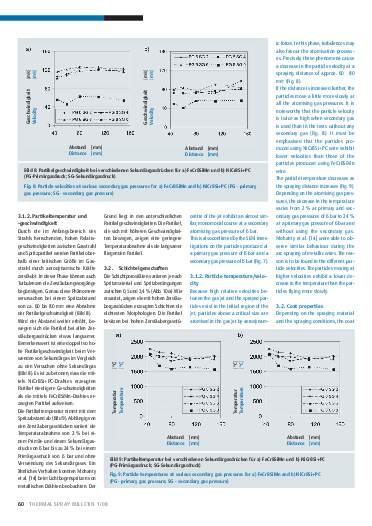

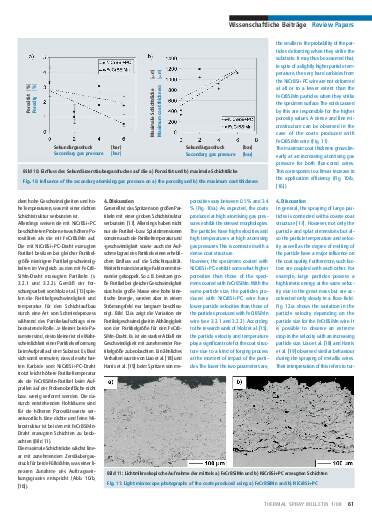

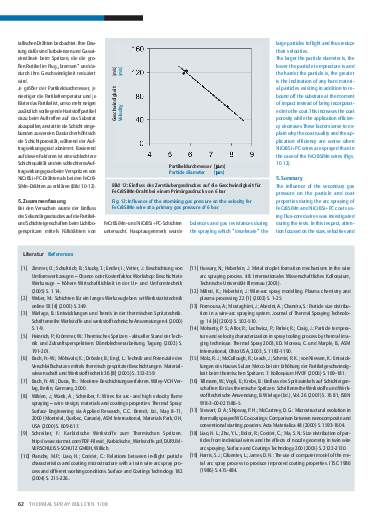

In order to be able to take advantage of the diverse possibilities of arc spraying using flux-cored wires, an important role is played by precise knowledge about the correlations between the process parameters, the particle properties and the coat properties. The influence of the atomising gas pressure on the particle properties and on the produced coat qualities is investigated in this article.Two Ni-based and Fe-based flux-cored wires were utilised.The AccuraSpray g3 measuring system and a test stand which we designed ourselves for particle size analysis were used for the characterisation of the particle properties in flight while the coat porosity and the maximum coat thickness of the deposited coats were determined with a light microscope and an optical 3D profilometer. Correlations between the particle and coat properties were established in this case.

Pages: 55 - 63

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription