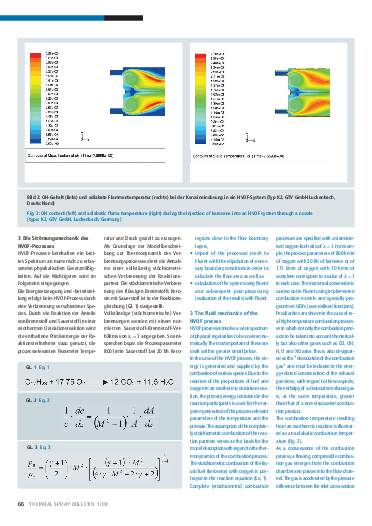

Holistic process simulation for thermal spraying -verified by the acoustic analysis of the HVOFprocess

Authors: Prof. Dr.Ing. habil. Bernhard Wielage, Dipl.-Ing. Gerd Paczkowski, Prof. Dr.-Ing. habil. Christian Rupprecht

The ever more stringent requirements on modern coating processes, particularly on thermal spraying technology, are demanding new, reliable methods for the mathematical description and prior calculation of the entire process chain. In the past, the simulation had to resort to extremely simplified numerical models

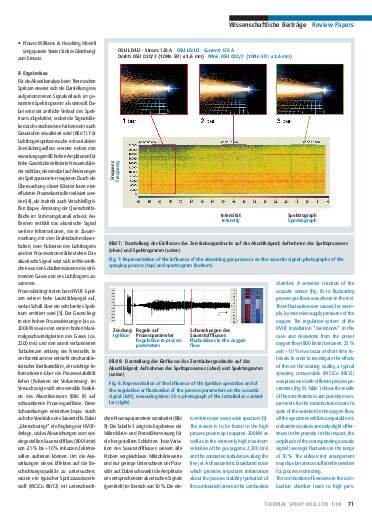

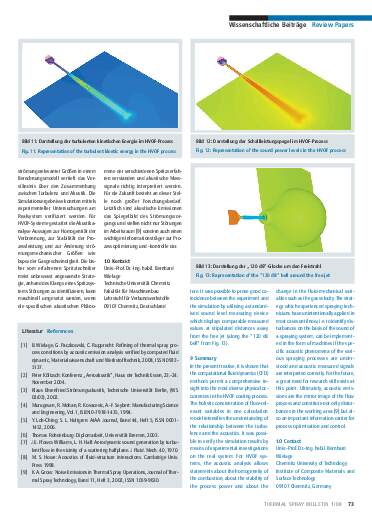

for the representation of the coating systems. By utilising solidly parallel computing architectures and efficient algorithms in order to describe complex thermodynamic processes, it is today possible to portray in one model all the descriptive variables starting from the combustion of the reaction species right up to the determination of the acoustic emissions of the flow field. The understanding of the process is improved in this way, thus permitting the efficient utilisation of simplified process diagnosis procedures such as acoustic analysis. The high noise emissions of the HVOF process which are basically caused by flowdynamic effects include important information which serves to assess the functioning capacity of the spraying system and of the quality assurance [1].

Pages: 64 - 73

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription