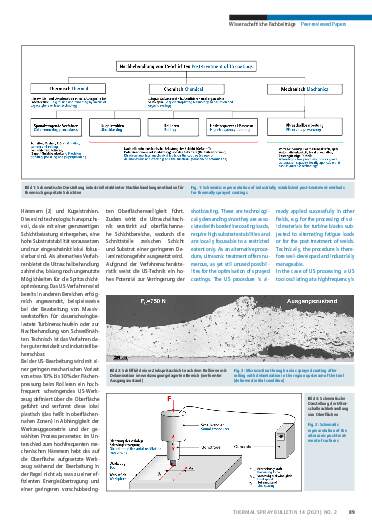

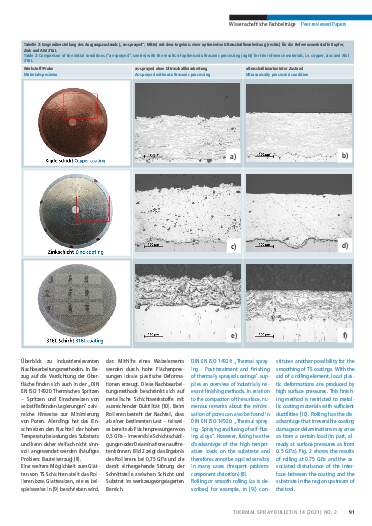

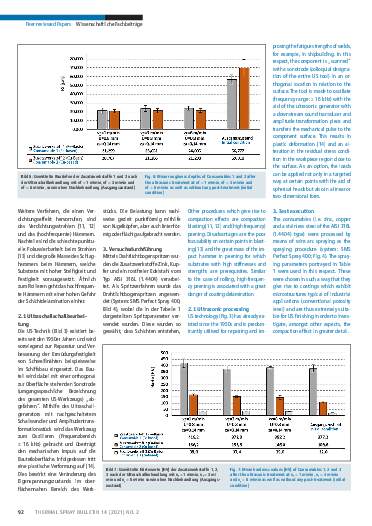

Compaction, smoothing and hardening of thermally sprayed coatings by means of ultrasonic machining

Authors: Prof. Dr.-Ing. habil. Christian Rupprecht, Dr.-Ing. Niyameddin Süleymanov, Dr.-Ing. Georg Thomas, M. Sc. Finn Martin, M. Sc. Marius Limburg, Prof. Dr. sc. techn. Michael Schneeweiß, Dipl.-Ing. Andreas Zinke, Dr.-Ing. Jan Glühmann

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.