Milling of thermally sprayed hardmetal coatings

Authors: Dr.-Ing. Lutz-Michael Berger, Dipl.-Ing. Jörg Spatzier, Dipl.-Ing. Carsten Hochmuth, Dipl.-Ing. (FH) René Georgi

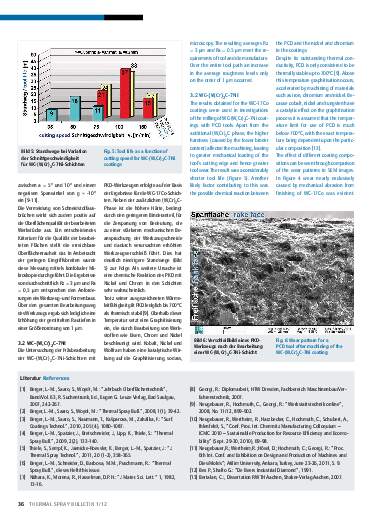

This work describes the development of finishing solutions by milling for

HVOF-sprayed WC-17Co and WC-(W,Cr)2C-7Ni coatings. The properties of

oxidation resistance, microstructure, hardness, Youngs modulus and fracture

toughness differ considerably between the two coating compositions.

Polycrystalline diamond (PCD) cutting tools proved to be the most favourable

for milling. The parameters could be optimised to achieve cost-efficient milling

of the WC-17Co coatings with an appropriate PCD cutting tool grade. In the

case of the WC-(W,Cr)2C-Ni composition a significantly lower machining tool

lifetime was reached due to the differences in the properties of the two

hardmetal coating compositions.

Pages: 33 - 37

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription