High-velocity oxy-fuel spraying with suspensions consisting of nanoscale and submicronscale oxide powders

Peer-reviewed Papers

Authors:

PD Dr. rer. nat. Andreas Killinger,

Dipl.-Ing. Andreas Rempp,

Dipl.-Ing. Andrei-Sorin Manzat,

Dipl.-Ing. Philipp Müller,

Prof. Dr. rer. nat. Dr. h. c. mult. Rainer Gadow

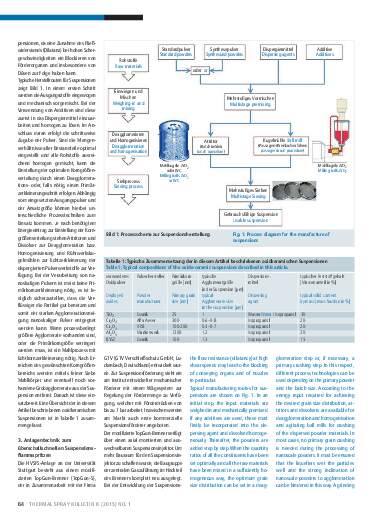

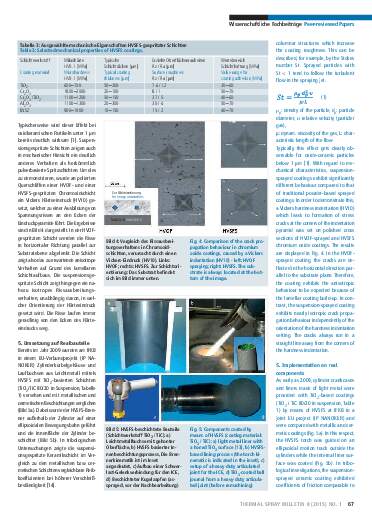

Thermal spraying of finely structured powder materials in the micronscale, submicronscale or nanoscale range can be carried out using agglomerated spraying powders which are processed with the well-known standard procedures such as atmospheric plasma spraying (APS) or high-velocity oxy-fuel (HVOF) spraying. As an alternative, there is the possibility of transferring such powders into a suspension by incorporating and stabilising them in a dispersing agent (e.g. water or alcohol). The relevant procedures are generally designated as suspension spraying. Reference is made to suspension plasma spraying (SPS) in the case of plasma spraying and to high-velocity suspension flame spraying (abbreviated as S-HVOF or HVSFS) for high-velocity oxy-fuel spraying. In principle, both methods are suitable for manufacturing coatings with particularly fine structural compositions. In this respect, HVSFS is particularly interesting for applications in which dense and well-adhering coating structures are demanded. The following treatise presents the latest work and results at the Institute for Manufacturing Technologies of Ceramic Components and Composites (IMTCCC) which have been obtained within the framework of the development of a suspension flame spraying torch. A few potential industrial applications are presented as well.

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.