Combined brazing and alitising process for thermally sprayed Ni-based alloys for the repair of turbine blades

Authors: Dr. rer. nat. Martin Nicolaus, Prof. Dr.-Ing. habil. Kai Möhwald, Prof. Dr.-Ing. Hans Jürgen Maier

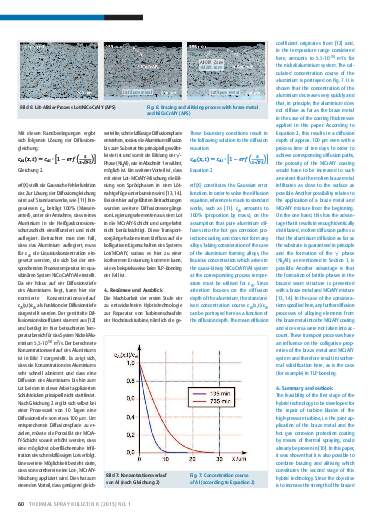

In this paper, a two-stage hybrid technology is developed for the near-net-shape repair of turbine blades. Not only aspects relating to process and fabrication engineering but also materials engineering mechanisms are incorporated into this technology. The process chain for the repair of turbine blades can be shortened with this hybrid technology. The turbine blades considered here are components of the high-pressure turbine and this paper therefore focuses on nickel-based alloys. The nickel-based braze metal needed for the repair of turbine blades is applied together with the hot gas corrosion protection coating by means of thermal spraying and the coating system is subjected to a combined brazing and alitising process.

Pages: 56 - 61

Order this article as a PDF for 8.00 Euro. Send us a short e-mail with your details.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription